Products

- Metal Casting

- Die Casting

- Sand Casting

- Gravity Casting

- Investment Casting

- Non Ferrous Casting

- Metalworking Service

- Metal Fabrication

- Sheet Metal Fabrication

- Metal Welding

- Metal Cutting

- Metal Bending

- Metal Plate Rolling

- Metal Roll Forming

- Metal Stamping

- Deep Drawn Stamping

- Expanded Sheet Metal

- Metal Perforating

- Plastic Molding

- Injection Molding

- Rotational Molding

- Blow Molding

- Thermoforming

- Precision CNC Machining

- EDM Machining

- Heat Treatment

- Surface Treatment

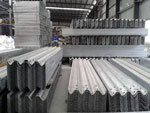

Metal Roll Forming

Roll forming is essentially a continuous bending operation performed on metal strip at room temperature. Tandem sets of rolls progressively shape the metal until the desired cross-sectional profile is achieved. Roll forming is ideal for producing parts with long lengths or in large quantities. It can also produce parts of multiple lengths from the same tooling. Maxtech provides solution of metal roll forming services to producing high quality affordable components, such as: roof sheet, highway guardrail, window and door taping, ridge tile, arched roof, shelves component and so on.

The metals materials used in roll forming: steel, aluminum, copper, stainless steel, galvalume, galvanized, galvannealed and electrogalvanized.

Metal Roll Forming (Roof Sheet, Highway Guardrail, Window and Door Taping, Ridge Tile, Arched Roof)

Custom Metal Roll Forming Service:

Maxtech is a professional supplier of metal roll forming service in China. We offer a reliable and low cost metalworking solution, such as: metal fabrication, sheet metal fabrication, structural metal fabrication, metal frame manufacturing, welding service, cutting service, metal bending, plate rolling, sheet folding, metal stamping, deep drawn stamping, expanded sheet metal and metal perforating.

We also provide the following services:

1. CNC Machining and EDM Machining Service

2. Heat Treatment:

Hardening, Annealing, Normalizing, Stress Relieving, Softening, and Graphitization

3. Surface Treatment:

Metal Polishing (Metal Mirror Polished, Brushed Metal Finishing), Shot Blasting, Sandblasting, Spray Painting, Powder Coating, Thermal Spraying, Anodizing, Chrome Plating, Nickel Electroplating / Electroless Nickel Plating, Hot-Dip Galvanizing, Copper Plating, Phosphorizing, Electrophoresis and Passivation

4. Assembly

5. Packing

6. Testing Report, QC Report